- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

What Are the Advantages of Laser Cutting?

The purpose why engineers pick a laser slicing carrier lies with the lengthy listing of upsides it offers. The blessings of laser slicing are flexibility, precision, repeatability, speed, cost-effectiveness, brilliant quality, contactless cutting, versatility and automation possibilities.

Read MoreWhat is Laser Marking

Laser marking is the method of changing the appearance of a object to produce a contrasting mark via an oxidation process. This oxidation is executed by means of slowly heating the object with low strength to draw the carbon to the appearance, producing a legible marking.

Read MoreTypes of Laser Cutting

This working way can be divide into three kinds methods - CO2 laser (for cutting, boring, and engraving), and neodymium (Nd) and neodymium yttrium-aluminium-garnet (Nd:YAG), which are equal in style, with Nd being used for excessive energy, low repetition boring and Nd:YAG used for very high-power b......

Read MoreHow Does Laser Cutting Work?

Where the laser reducing procedure wishes to begin somewhere different than the aspect of the material, a piercing method is used, whereby a excessive strength pulsed laser makes a gap in the material, for instance taking 5-15 seconds to burn thru a 0.5-inch-thick (13 mm) stainless metal sheet.

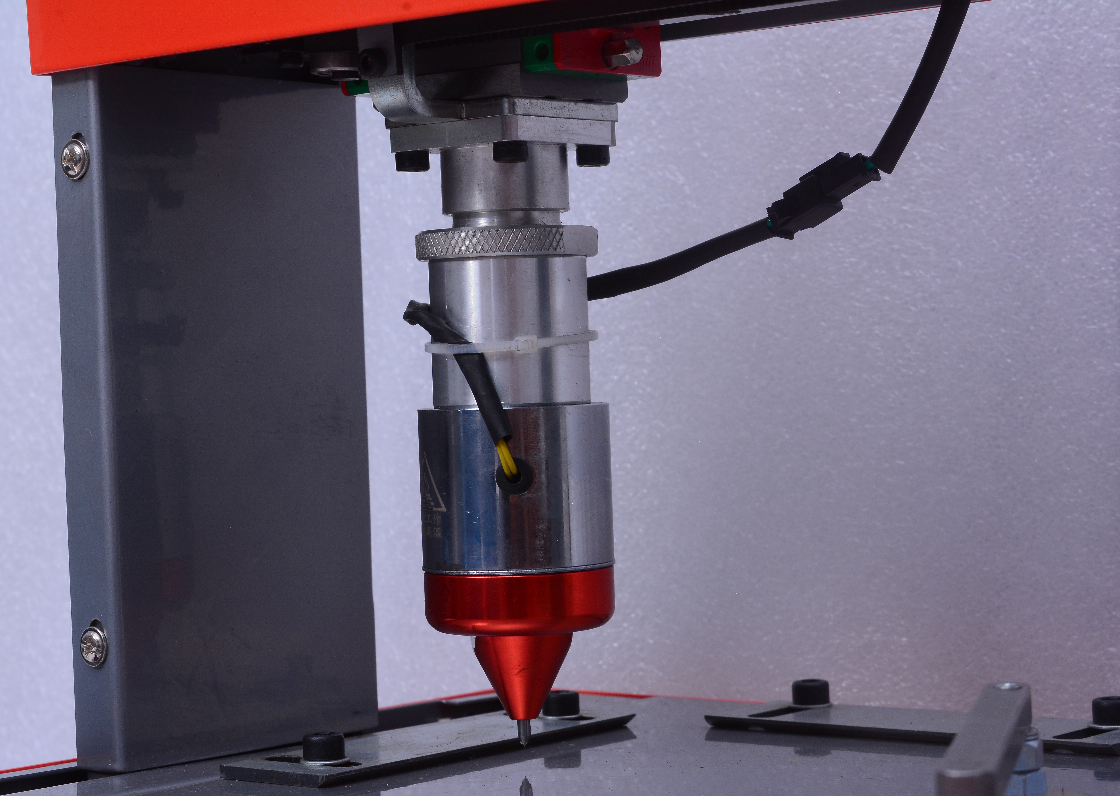

Read Morewhat is dot peen marking?

Dot Peen marking or engraving is a pin marking equipment that permits producers to make deep, everlasting impressions in a range of substances for identification and traceability. Also named as "pin marking," "dot peening," or "pin stamping", this fast, environment friendly marking system entails a......

Read More